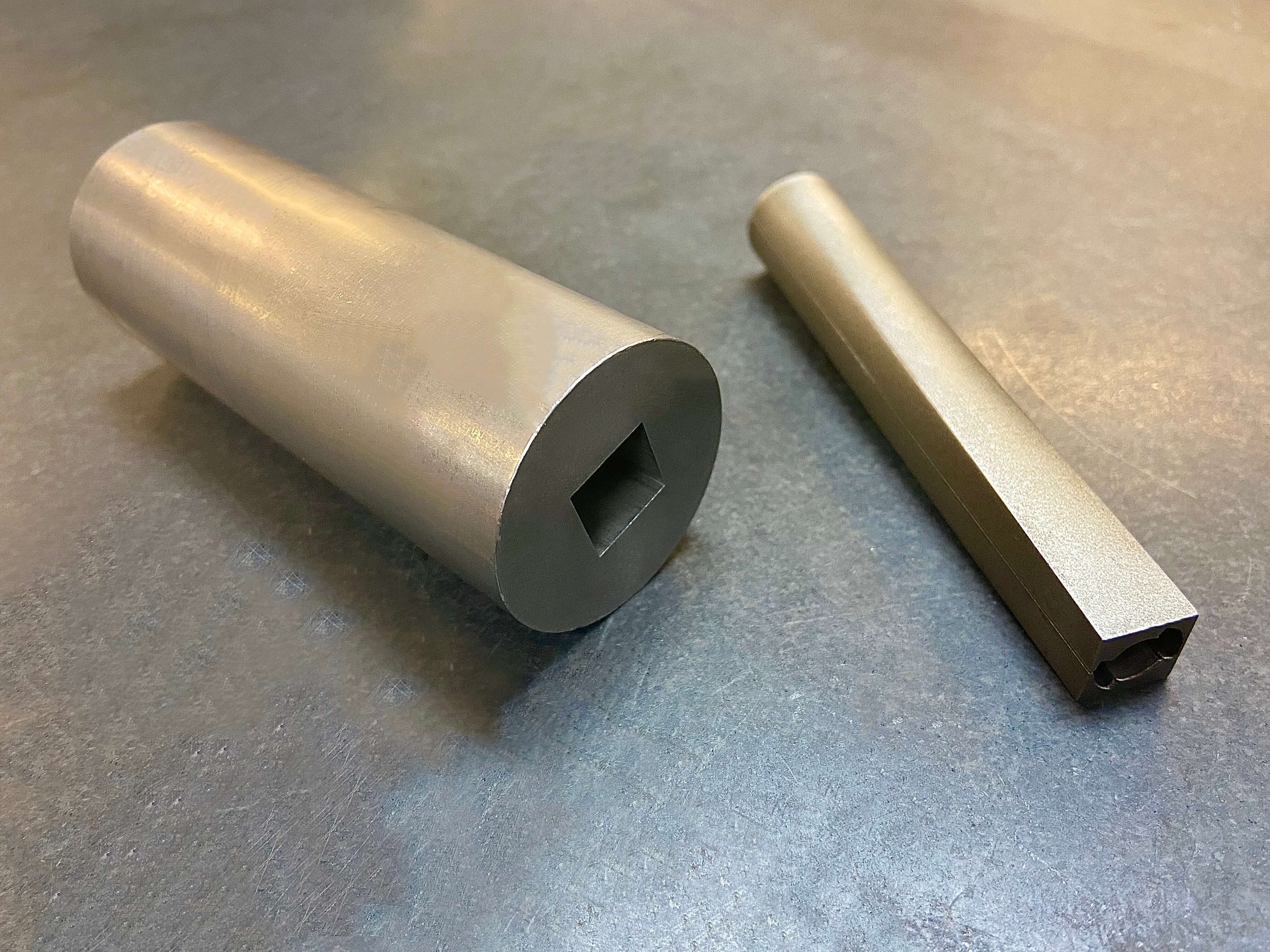

Every Precision Machined Part Has a Story

In our precision machine shop, we know from experience that context matters.

Once, after making a three-toothed brass gear for a customer’s machine, they informed us that the gear was wearing out quickly.

Puzzled by this outcome, we asked for more information on the part’s use. When we learned that it was being mated with a gear made from hardened steel, the reason for the wear and tear became clear. The difference in hardness between the two gears was too significant, meaning the softer brass gear was bound to wear down faster than usual.

Once we knew the full context for the part, it was easy to make a replacement that would perform much better in the application. Rather than choosing brass, we selected a harder alternative—an aluminum-bronze alloy. This material held up much better to the steel mating gear, and our solution provided lasting value to the customer.

Scenarios like this one have taught us to always ask questions about how the part we’re making fits into the greater whole of its end-use application.

Asking the Right Questions

Like a country music star, every part has a story.

Sometimes, the story is simple, as when a customer requests a repeat part. In these cases, a dialogue with a customer may not be necessary to ensure superior results. We can likely jump right into precision machining.

More often than not, however, we’ll need to ask a few questions to gain a big-picture understanding of a part and determine how to best approach its manufacturing process. Certain details can’t be explicitly called out in a drawing, so it’s our responsibility to ask questions to uncover that information.

When you work with us, don’t be surprised if we ask a few questions about your part’s intended fit, form, and function.

Fit

Where will the part fit in the application? How tight will the fit need to be?

Knowing where the part will be placed allows us to determine whether it has been toleranced properly in the drawing.

Is it a mating part? If so, what are the characteristics of the part to which it is mating?

As the brass gear example illustrates, understanding the intended mate for a part is key to choosing the right material and manufacturing capabilities.

Form

What characteristics does the part need to have? How can it be machined most efficiently?

The details about a part’s desired shape, thickness, and smoothness help us narrow our material choices and determine the optimal manufacturing process. Certain parts need only a simple cut around the edges, whereas more complex parts may require advanced solutions such as multi-axis machining.

By asking form-related questions, we can find the most efficient way to machine a part to get it to you as quickly and cost-effectively as possible.

Function

What will your part do? How durable does it need to be?

The intended function of a part is perhaps the most important factor to consider when deciding on the ideal material and manufacturing method.

In some cases, a customer may request a material that is expensive or hard to find. Although we’ll do our best to source any material you need, we may recommend an in-stock alternative that will ensure equal—or better—performance for your application, saving you time and money.

When we understand how a part will function, we can also draw on our wealth of mechanical and engineering expertise to create parts that won’t wear down or break easily.

For instance, if we discover that a part will bear weight or be in a corrosive environment, we’ll recommend specific solutions to ensure the part’s longevity. Chances are, someone on our team has made a similar part for a similar application, and their background knowledge can help us avoid any manufacturing pitfalls.

Consult with Our Experts

At Arbiser Machine, we’re more than precision machining experts; we also serve as manufacturing consultants for our customers. Our engineers have extensive knowledge of DFM best practices, materials, and metallurgy, so you can rest assured that you’re in good hands.

We’re even happy to collaborate with you live within our quoting portal to discuss your project in real time.

When we take the time to get to know your part’s story, we can ensure greater efficiency and superior results. It’s one reason we’re the go-to precision machine shop for quick turnaround parts in the Greater Atlanta area!

Request a quote to work with us!